To keep production efficiency high in the increasingly complicated electronics manufacturing process, precise component counts are essential. X-ray technology has recently taken the lead as a trustworthy and accurate way to check the quantity of components on reels, particularly for surface mount devices (SMD). Since they are non-invasive and have a high throughput, X-ray SMD component counters are becoming more popular.

Intelligent Labeling with PassionIOT’s AI-Powered Solutions

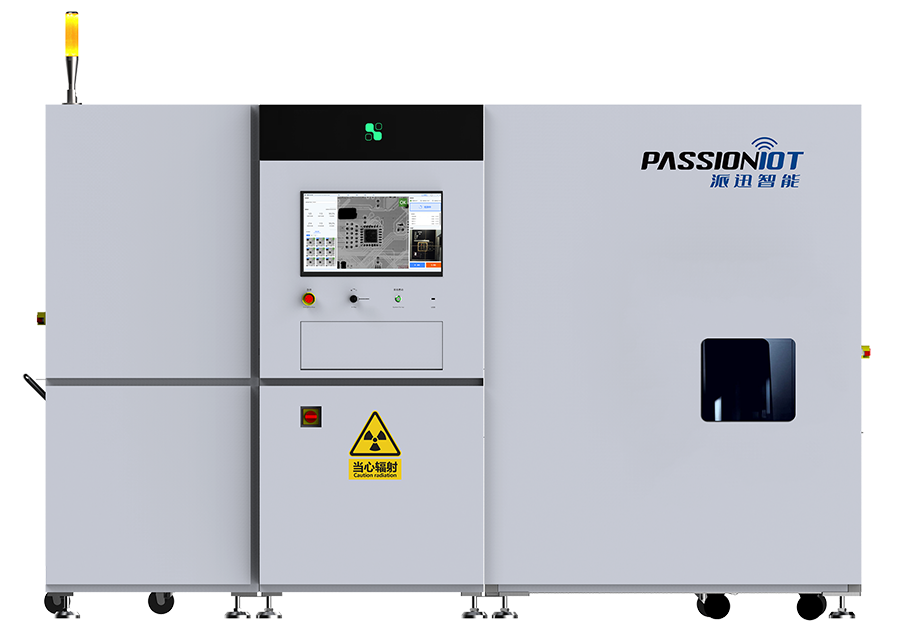

One example of advanced innovation in this space is the Inline X-Ray Reel Counter from PassionIOT, a company specializing in smart factory automation. This counter integrates x ray technology with AI-driven features such as automatic label positioning. Unlike traditional systems, PassionIOT’s AI labeling system identifies blank areas on the reel surface, ensuring accurate and efficient label placement.

PassionIOT’s counter supports a wide range of reel types, including heights up to 90 mm and various material formats, making it highly adaptable to different production environments. Its AI-assisted systems reduce human error and streamline labeling workflows, ultimately improving traceability and inventory control.

Why X-Ray SMD Component Counters Are Industry-Critical

Modern SMT lines depend on accurate component tracking to minimize downtime and avoid costly errors. With x ray SMD component counter systems, manufacturers can count components through sealed packaging, preserving reel integrity and reducing the need for manual inspection.

Incorporating x ray technology into the supply chain offers a strategic advantage by improving data accuracy and production readiness. X ray SMD component counters offer a consistent solution for manufacturers aiming to implement leaner processes without compromising reliability.

Conclusion

As production demands evolve, integrating tools like PassionIOT’s X-ray reel counters isn’t just a technological upgrade—it’s a smart transition into a more transparent and data-driven workflow. In the mosaic of modern electronics, precision is no longer optional—it’s foundational.