In the rapidly evolving sector of industrial automation, the demand for precision components is driven by the need for efficiency and reliability. Sourcing high-quality CNC turning services is the first step toward achieving operational excellence. By consolidating manufacturing processes and leveraging strategic logistics, companies can reduce lead times and ensure the seamless assembly of complex automated systems. This article examines strategies for streamlining supply chains and optimizing component precision.

Unifying Procurement and Precision with Advanced Machining

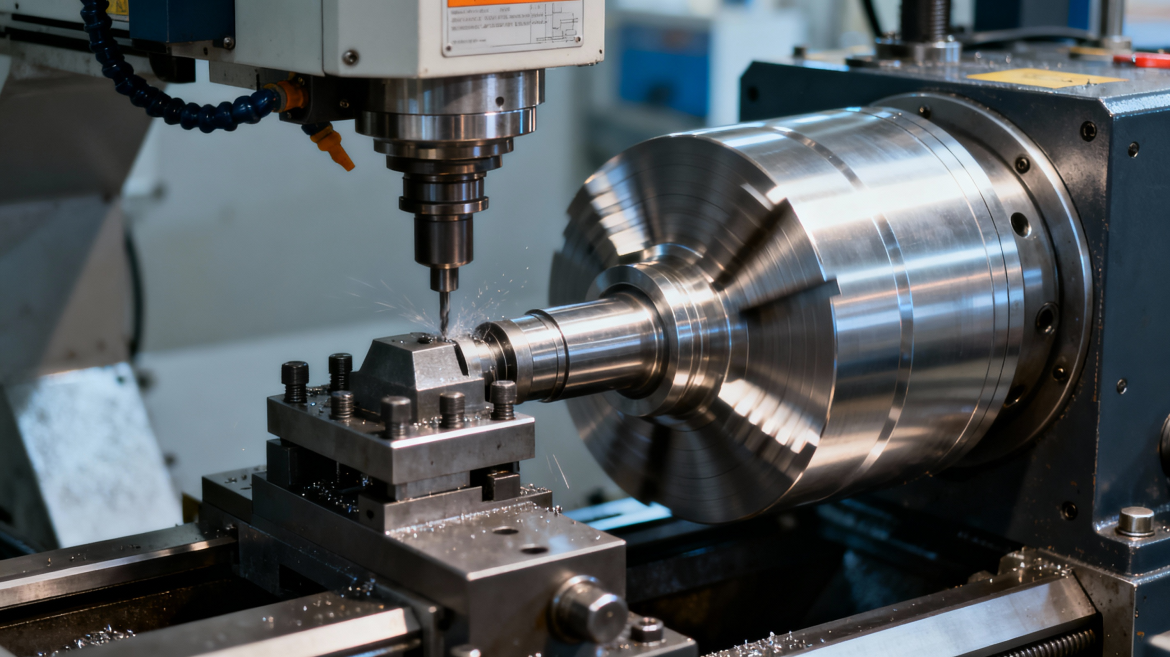

Consolidating the supply chain through a versatile CNC turning service manufacturer allows engineers to mitigate risks associated with multi-vendor sourcing while maintaining strict dimensional accuracy for automation components.

Streamlining Supply Chains for Cost Efficiency

Managing multiple vendors for raw materials, machining, and finishing often results in administrative bottlenecks and tolerance stack-up issues. By centralizing production, companies can significantly reduce overhead costs—often by up to 15%—associated with vendor management. A unified approach ensures that medical and automotive-grade alloys are sourced and processed under a single quality management system (QMS). Comprehensive CNC turning and milling services allow for the complete fabrication of complex geometries, such as hydraulic valve spools and robot joint components, in one setup. This “done-in-one” capability not only accelerates production velocity but also minimizes the handling errors inherent in transferring parts between different service providers.

Achieving Micron-Level Consistency

For industrial automation, component failure is not an option. Precision is paramount, especially when machining superalloys like Inconel or lightweight titanium for medical implants. Advanced CNC turning centers equipped with live tooling can achieve concentricity and diameter tolerances as tight as ±0.005 mm. This level of precision is critical for high-stress environments where parts must withstand repetitive motion without degradation. Implementing unified quality control standards across production batches ensures that every shaft and fastener meets identical specifications, reducing the rejection rate at the assembly line and guaranteeing the longevity of the final automation product.

Strategic Logistics: Navigating Global and Local Manufacturing

Balancing the immediate availability of local providers with the scalability of global manufacturing hubs is crucial for optimizing logistics costs and ensuring Just-in-Time (JIT) delivery.

Leveraging Global Hubs via Savannah Ports

When searching for CNC turning services savannah or similar logistics hubs, procurement directors often weigh the benefits of proximity against the cost advantages of global sourcing. While local shops offer rapid turnaround for prototypes, international manufacturers often provide superior scalability for mass production. The Port of Savannah, acting as a critical gateway for CNC turning services georgia and the broader Southeast, facilitates the efficient import of high-volume components. By utilizing these established logistics channels, companies can maintain a lean inventory while accessing the “High-Mix Low-Volume” (HMLV) capabilities of global partners. Strategic sourcing involves utilizing local vendors for R&D iterations while routing standardized, volume-intensive parts through global supply chains that connect seamlessly to major US distribution points.

Adapting to High-Mix Low-Volume Demands

Modern industry trends, particularly in Consumer Electronics and EV sectors, require flexible production lines capable of rapid adaptation. A reliable manufacturer must support HMLV models to accommodate frequent design iterations. Whether it is transitioning an EV motor shaft from prototype to mass production or customizing sensor housings, the ability to scale output without compromising quality is a key differentiator. Global partners integrated with smart technologies can offer transparent data tracking, ensuring that shipments arriving through Georgia ports align perfectly with domestic assembly schedules.

Livepoint Tooling: Precision Manufacturing Excellence

Livepoint Tooling stands as a premier partner for B2B professionals seeking reliable, high-precision manufacturing solutions. With over 23 years of expertise in the industry, Livepoint specializes in delivering consistent quality for complex industrial needs.

Certified Quality Systems: Livepoint operates under strict ISO 9001 and IATF 16949 certifications, ensuring that every component meets rigorous automotive and industrial standards.

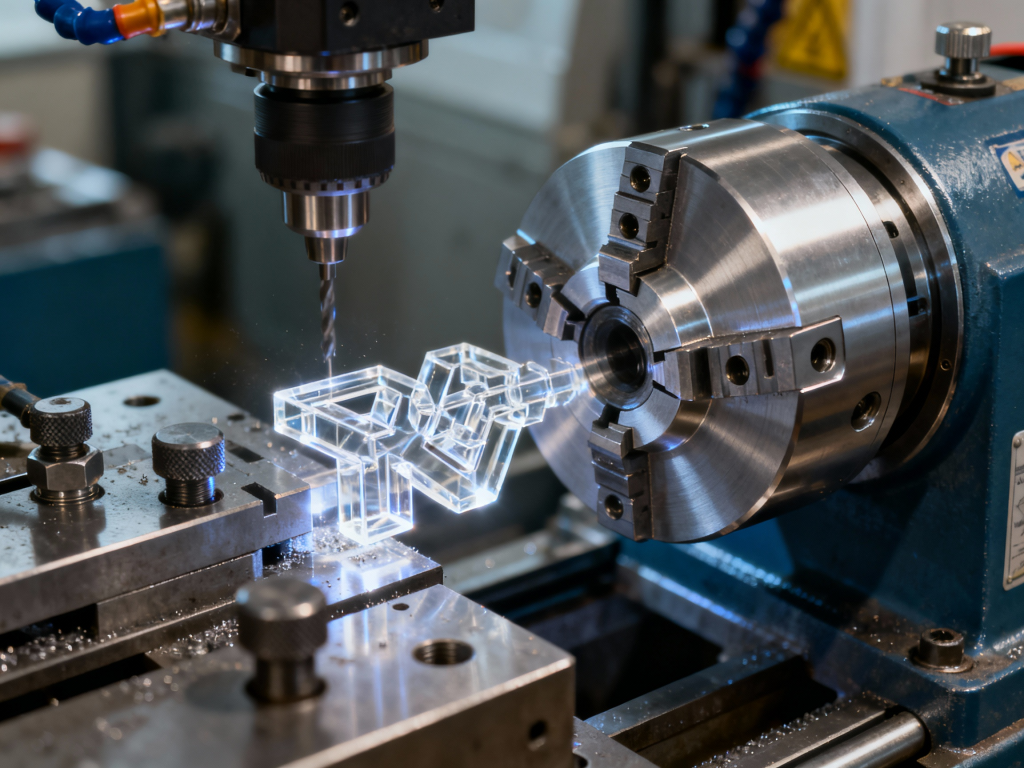

Comprehensive Service Range: From CNC turning services to 3-axis milling, grinding, and EDM, Livepoint offers a true one-stop solution for materials ranging from aluminum and steel to titanium and engineering plastics.

Global Reach: Headquartered in Shenzhen, Livepoint efficiently serves the global market, providing “High-Mix Low-Volume” flexibility that rivals local providers in speed and exceeds them in scalability.

For engineers and procurement managers aiming to consolidate their supply chain and ensure flawless execution, Livepoint Tooling delivers the expertise required to turn ambitious concepts into reality.