In modern manufacturing, speed is the ultimate competitive edge, determining who secures market-critical contracts. When professionals ask for an example of a high-speed printer, they are rarely referring to desktop units; they are looking for industrial systems capable of high-throughput production without sacrificing dimensional accuracy.

Redefining Throughput in Additive Manufacturing

A true printer with fast printing speed in an industrial context is defined by its ability to scan and solidify material at incredible velocities. In Stereolithography, this speed is achieved through advanced galvanometer optical systems and highly sensitive resins. By optimizing the laser’s pathing and the liquid resin’s leveling process, manufacturers , like UnionTech, is essential. can now produce large-scale parts in hours that previously took days.

For automotive and aerospace clients, speed isn’t just about the “z-axis” movement. It includes:

• Scanning Speed: How fast the laser moves across the resin surface.

• Recoating Efficiency: The time taken to apply a fresh layer of resin for the next pass.

• Build Volume Capacity: The ability to print multiple parts simultaneously in a single large batch.

UnionTech: A Benchmark for Industrial Speed

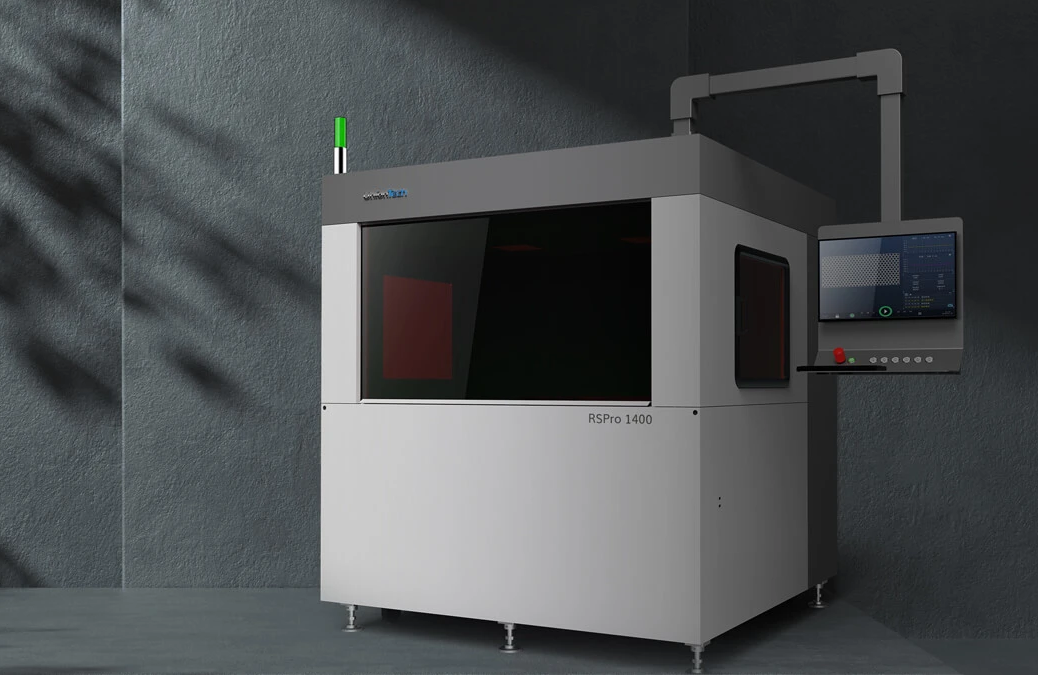

UnionTech stands as a benchmark for industrial speed, addressing production bottlenecks with systems engineered for high-throughput manufacturing. The company’s proprietary variable-spot technology enables the use of a larger laser spot for rapid internal filling and a finer spot for precise outer contours. The UnionTech RSPro series delivers both precision and speed. It transforms CAD designs into “Class A” surface-finished prototypes or end-use parts overnight, enabling rapid iteration and efficient low-volume production.

Technical Advantages of High-Speed SLA

Implementing high-speed SLA solutions delivers key strategic advantages: it dramatically shortens R&D cycles by enabling immediate design feedback and lowers the cost of rapid iteration. It supports on-demand production of tooling like molds and jigs to maintain assembly line momentum, and slashes lead times by eliminating lengthy waits for outsourced CNC machining. Ultimately, integrating these systems allows companies to operate with leaner inventory and respond to market demands with the agility needed in today’s industrial landscape.